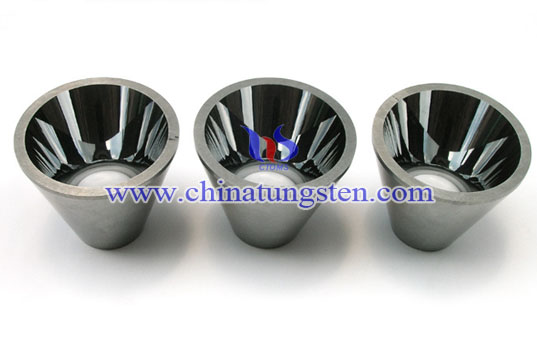

Tungsten Carbide Sandblasting Nozzle

Tungsten carbide sandblasting nozzle also known as tungsten steel nozzles, type has a single inlet, double inlet and Venturi nozzles. With high wear resistance, high hardness, high elastic modulus, high compressive strength, corrosion resistance, high impact resistance and other advantages. 30 times the wear life of steel, is three times the fine ceramic composite industry. As long as a negative high-pressure compressed air can rust, clean the surface of SA2.5-3.0 grade level. In hardware and machinery, casting rust polished glass mirror art of carving, sandblasting and other applications, are required preparation and sandblasting machine supporting tungsten carbide sandblasting nozzle.

By their nozzles are in a variety of different designs of spray conditions, which use suitable nozzles needed to achieve optimum spray performance in use. Characteristics of the nozzle spray nozzle is mainly reflected in the type of shape that liquid from the nozzle opening formed and its operating performance. Named one spray nozzle is divided into a fan shape, tapered, solid stream (ie jet), air atomizing, flat nozzle, which is divided into a hollow cone nozzle cone and full cone two categories; while Venturi nozzles (i.e. mixing nozzle), strong cold (hot) and the outlet nozzle for hair tuyeres is reflected in the naming of the operating performance of the nozzle.